Journal of Magnetism and Magnetic Materials 285, 279 (2005)

A. Bollero, M. Ziese, R. Höhne, H.C. Semmelhack, U. Köhler, A. Setzer and P. Esquinazi

Abstract

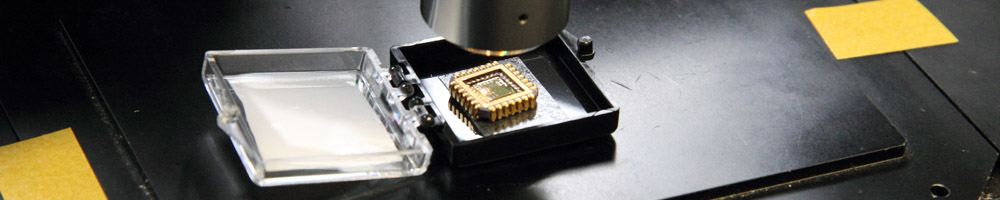

The pulsed laser deposition technique has been used to produce magnetite (Fe3O4) films with thickness ranging from 26 to 320 nm grown on MgAl2O4 (1 0 0) substrates. Microstructural characterisation of the films has revealed enlarged grains with increasing thickness, i.e. deposition time. Magnetisation hysteresis loops have been measured at different temperatures in the range 25–300 K for three samples: two films with thickness of 26 and 320 nm deposited on MgAl2O4 (1 0 0) and, for comparison, a 30 nm thick film deposited on MgO (1 0 0). The evolution of the remanence and the coercivity with temperature shows significant differences between the thinner films and the thicker one which are explained in terms of the effect of the interfacial strain as well as the influence of the deposition time on the grain sizes and the variation in the density of antiphase boundaries. All the studied films exhibit a minimum of the coercivity at about 130 K, the temperature at which the magnetocrystalline anisotropy constant K1 vanishes for the bulk material.