Our research focus

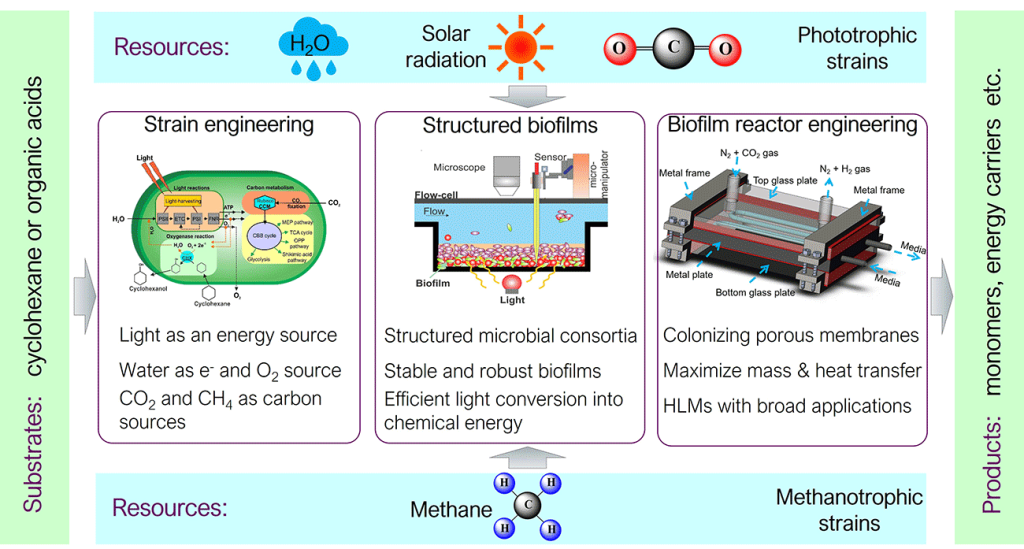

In BioMat, we learn from ingenious designs, concepts, and applications found throughout nature to develop unique hybrid living materials (HLMs) using biofilms. These developments will be pursued by combining the following biological, and technical aspects:

- Designing microbial consortia to exploit the metabolic plasticity of photoautotrophic, heterotrophic, and methanotrophic strains for harvesting the maximum amount of CO2 and/or CH4 and solar radiation. Thus, utilizing maximal natural resources and establishing energy-efficient and cost-effective HLMs systems for production purposes.

- Employing microbial biofilms and thereby utilizing the self-immobilization, self-regeneration, and self-adaptation characteristics to retain biomass and generate high-cell-density (HCD) culture. Here, we aim to design structured microbial communities in stable biofilms for efficient light conversion into chemical energy.

- Designing and construction of biofilm-based reactor modules to generate HCD culture for the continuous production of chemicals and energy carriers. At the same time, we will construct prototypes that demonstrate the scaling of HLMs using the numbering-up approach to enhance catalytic surface area and product throughput.

Our Projects

REPLACER: Recycling plastic and developing hybrid living materials by capturing greenhouse gases to produce value-added products

The innovative concept of REPLACER is to combine renewable living materials with porous recycled plastic to develop new sustainable technologies. We will grow synergistic microbial biofilm consortia in porous plastic scaffolds that sequester greenhouse gases such as carbon dioxide and methane and produce microbial proteins as a value-added product.

Funding source

- M-ERA.NET

Principal Investigator (PI)

Dr. Ing. Rohan Karande (Coordinator), Prof. Dr. Tilo Pompe, Prof. Dr. Frank Cichos, Prof. Dr. Oskar Hallatschek, Dr. Susanne Ebitsch

Partners

- qCoat GmbH Leipzig

- Holisun SRL Romania

- Leibniz Institute for Surface Modification (IOM)

- University of Latvia

Advisory board

- Puevit GmbH

- SMWA (Saxon State Office for Environment, Agriculture and Geology)

- University Leipzig, Equal Opportunities Unit

Duration

05.06.2023 – 31.05.2026

LigNylon: Electrochemical hydrogenation of lignin-derived mixtures of aromatic compounds for microbial synthesis of Nylon monomers

LigNylon will develop a cost-effective and sustainable process for biobased monomers for

Nylon, the most abundant synthetic textile. It will exploit renewable feedstock and electric

energy instead of fossil resources and develop a laboratory scale process designed to reach

technical scale.

Funding source

- Helmholtz transbig

Principal Investigator (PI)

Dr. Ing. Rohan Karande, Prof. Dr. Tilo Pompe

Partners

- Helmholtz Centre for Environmental Research – UFZ (Prof. Harnisch, Project leader)

- Domo Caproleuna GmbH

Duration

01.10.23 − 30.09.2025

Analysis and Prediction of Complex Microbial Community Functions in Hybrid Living

Materials

Funding source

- Seed Funding SCADS.AI

Principal Investigator (PI)

Prof. Dr. Frank Cichos

Partners

- Max Planck Institute for Human Cognitive and Brain Sciences (Dr. Nico Scherf)

Duration

01.10.2023 − 31.12.2024

LivMat: Productive catalytic living materials: combining 3D biobased fibrillar membranes with synthetic microbial consortia to produce chemicals

In nature, materials with unique renewable, recyclable, and biodegradable potential are built and evolved from natural resources to provide the most effective designs and systems. Such naturally evolved concepts and systems inspire and set the basis for the LivMat project to design catalytic living materials (cat-LMs) and overcome fundamental efficiency, robustness, and scalability issues associated with current state-of-art technologies.

Specific innovation objectives and results: The LivMat project aims to syndicate 3D biobased porous materials with synthetic microbial consortia to effectively capture natural and waste resources and develop cat-LMs to synthesize chemicals continuously. Utilizing a machine and deep learning-based platform for integrated data analysis and system optimization will grant predictive power and deliver actionable knowledge to achieve high-performance cat-LMs. As a result, the LivMat team will demonstrate and scale cat-LMs-based bioreactors up to TRL 5 for continuous production of biobased monomers (at least 100 g), such as adipic acid or ɛ-caprolactone, as model compounds. Thus, the LivMat project supports the transition towards the circular economy and the European Green Deal by developing material and energy-efficient cat-LMs-based bioreactor platforms beyond the current state-of-art technologies for chemical production. In the future, these cat-LMs bioreactors could be transferred to environmental or space biotechnological sectors.

Needs addressed: The LivMat project benefits from an interdisciplinary network to facilitate cat-LMs development and knowledge by exploiting 3D material design and creating functionalities using microbial consortia for chemical production. By creating excellent science and research for innovative cat-LMs applications, the LivMat project develops robust and efficient sustainable technologies for chemical synthesis, which is bound to strengthen interdisciplinarity and support the innovation chain.

Impact and potential benefits: The overall cat-LMs development and their applications for producing bio-monomers such as ɛ-caprolactone and adipic acid, including CO2 sequestering, will be subjected to life cycle assessment (LCA) in the context of Responsible Research and Innovation (RRI). This will enable us to estimate the environmental impacts and address socio-ecological benefits that support several global societal challenges (SDGs 2, 9, 12, and 13).

Funding source

- M-ERA.NET

Principal Investigator (PI)

Dr. Ing. Rohan Karande (Coordinator), Dr. Susanne Ebitsch (Project management), Prof. Dr. Tilo Pompe, Prof. Dr. Frank Cichos

Partners

- Solaga GmbH Leipzig / Berlin

- UFZ, Prof. Katja Bühler

- Istanbul Technical Univeristy

- Kaunas University of Technology

- University of Latvia

Associated partners

- WEARONICS Technology Ltd.

- Association of the Chemicals Industry (VCI)

- biosaxony e.V.

- iDiv Research Greenhouse

Duration

01.07.2024 – 30.06.2027

BIOWIN: AI-supported biotechnology for resource-efficient active ingredient and bio-nylon production

The main objective of the project is the development of innovative and sustainable technologies for the production of active ingredients and chemicals based on renewable resources. Today’s pharmaceutical and chemical industry is mainly based on energy-intensive petrochemicals and is therefore facing a fundamental shift towards the energy- and land-efficient utilisation of renewable resources. The dependence on fossil energy and rising energy prices are currently directly affecting our industry. BASF, for example, recently closed two energy-intensive ammonia plants at its Ludwigshafen site and announced the loss of 2,600 jobs. This project aims to develop resource- and energy-efficient bioprocesses with the help of artificial intelligence (AI) and in-silico modelling. This includes two product areas, the antifibrinolytic active ingredient ε-aminocaproic acid (ACA) and monomers as building blocks of bio-nylon.

The production strategies for both product classes are based on the same artificial metabolic pathways (in vivo cascades) developed at the UFZ and Leipzig University, which are to be further optimised and brought into suitable process setups. The development of the process setups is supported by or based on AI approaches.

Funding source

- SAB /JTF Joint project

Principal Investigator (PI)

Dr. Ing. Rohan Karande

Partners

- Helmholtz Centre for Environmental Research – UFZ (Prof. Bruno Bühler, Coordinator)

- Max Planck Institute for Human Cognitive and Brain Sciences (Dr. Nico Scherf)

Duration

01.04.2024 − 30.06.2026

SPP 2451: Engineered Living Materials with Adaptive Functions

Combining stimuli-responsive hydrogels and scaffold-supported microbial biofilms for a self-controlled catalytic activity of a microbial leaf

Funding source

- DFG SPP 2451

Principal Investigator (PI)

Prof. Dr. Tilo Pompe, Dr. Ing. Rohan Karande

Partners

- Leibniz Institute for Surface Modification (IOM), Dr. Agnes Schulze

Duration

01.04.2024 − 31.03.2027

Our Group

GROUP LEADER

Scientific career

Since 2021

Junior Research Group Leader “Bioactive systems for controlled evolutionary materials”, Research and Transfer Center for bioactive Matter (bACTmatter), University of Leipzig, Germany

Since 2021

Guest scientist at the Department of Solar Materials (SoMa),

Helmholtz Centre for Environmental Research, Leipzig, Germany

2014 – 2021

Scientist at the Department of Solar Materials (SoMa), Helmholtz Centre for Environmental Research, Leipzig, Germany

2012 – 2014

Post-doctoral Researcher at the Laboratory of Chemical Biotechnology, TU Dortmund University, Dortmund, Germany

2007 – 2012

Dissertation at the Laboratory of Chemical Biotechnology,

TU Dortmund University, Dortmund, Germany

2004 – 2007

Master of Science in Chemical Engineering (M. Sc.) with specialization in Biochemical Engineering, TU Dortmund University, Dortmund, Germany

1999 – 2003

Bachelor in Chemical Engineering (B.E), Shivaji University (P.V.P Institute of Technology), Kolhapur, India

Selected publications

- Bretschneider L, Heuschkel I, Bühler K, Karande R, Bühler B Rational orthologous pathway and biochemical process engineering for adipic acid production using Pseudomonas taiwanensis VLB120. Metabolic Engineering, accepted

- Bretschneider L, Heuschkel I, Ahmed A, Bühler K, Karande R, Bühler B

Characterization of different biocatalyst formats for BVMO-catalyzed cyclohexanone oxidation

Biotechnology and Bioengineering - Salamanca D, Bühler K, Engesser K-H, Schmid A, and Karande R*

Whole-cell biocatalysis using the Acidovorax sp. CHX100 Δ6HX for the production of ω-hydroxycarboxylic acids from cycloalkanes. New Biotechnology, 2021, 60, 200-206. - Heuschkel I, Hanisch S, Volke D, Löfgren E, Hoschek A, Nikel P, Karande R, and Bühler K Continuous production of polycaprolactone monomers from cyclohexanone using engineered Pseudomonas taiwanensis VLB120 biofilms in drip-flow and rotating bed reactors Engineering in Life Sciences, 2021.

- Bretschneider L, Wegner M, Bühler K, Bühler B, and Karande R

One-pot synthesis of 6-aminohexanoic acid from cyclohexane using mixed-species cultures

Microbial Biotechnology, 2020, 1-15 - Heuschkel I, Dagini R, Karande R, and Bühler K The impact of glass material on growth and biocatalytic performance of mixed-species biofilms in capillary reactors for continuous cyclohexanol production Frontiers in Bioengineering and Biotechnology, 2020, 8, 1090-1100

- Hoschek A, Heuschkel I, Schmid A, Bühler B, Karande R, and Bühler K

Mixed-species biofilms for high-cell-density application of Synechocystis sp. PCC 6803 in capillary reactors for continuous cyclohexane oxidation to cyclohexanol

Bioresource Technology, 2019, 282, 171-178 - Karande R, Salamanca D, Schmid A, and Buehler K Biocatalytic conversion of cycloalkanes to lactones using an in-vivo cascade in Pseudomonas taiwanensis VLB120 Biotechnology and Bioengineering, 2018, 115, 2, 312-320

- Karande R, Schmid A, and Buehler K

Applications of multiphasic microreactors for biocatalytic reactions

Organic Process Research & Development, 2016, 20, 361-370 - Karande R°, Halan B°, Schmid A, and Buehler K*

Segmented flow is controlling the growth of catalytic biofilms in continuous multiphase microreactors

Biotechnology and Bioengineering, 2014, 111, 1831-1840

°These authors contributed equally to this work - Karande R, Schmid A*, and Buehler K

Miniaturizing Biocatalysis: Enzyme-catalyzed reactions in an aqueous/organic segmented flow capillary microreactor

Advanced Synthesis and Catalysis, 2011, 353, 2511-2521

Patents

- WO/2020/052762

A composition of photoautotrophic microorganisms and chemoheterotrophic microorganisms in a biofilm

Karande R, Hoschek A, Heuschkel I, Bühler K, and Schmid A

2018 - WO/2018/046104

Microorganisms and a method for the production of lactones and their secondary products by converting cycloalkanes

Karande R, Salamanca D, Engesser K-H, Buehler K, and Schmid A

2016 - WO/2012/152337

Segmented flow biofilm reactor

Schmid A, Buehler K, and Karande R

2010

SENIOR SCIENTISTS

PhD STUDENTS

M.Sc. Nina Siebert

Leipzig University

Johannisallee 21-23

04103 Leipzig

Dipl.-Ing. Alexander Franz

Leipzig University

Johannisallee 21-23

04103 Leipzig

Dipl.-Ing. Selina Hanisch

Leipzig University

Johannisallee 21-23

04103 Leipzig

Dipl.-Ing. Valentina Schmitz

Leipzig University

Johannisallee 21-23

04103 Leipzig

Lea Seibert

Leipzig University

Johannisallee 21-23

04103 Leipzig

MASTER STUDENTS

Aathira Prakash

Hochschule Anhalt – Anhalt University of Applied Sciences

Campus Köthen

Diya Pollayil

Friedrich Schiller Universität

Jena

Malabika Bera

Hochschule Anhalt – Anhalt University of Applied Sciences

Campus Köthen

Tanisi Ramprasad

Martin Luther Universität Halle-Wittenberg

Cooperations

Our junior research group works closely with the Working Group Catalytic Biofilms of the Solar Materials Department at the Helmholtz Centre for Environmental Research GmbH (UFZ).